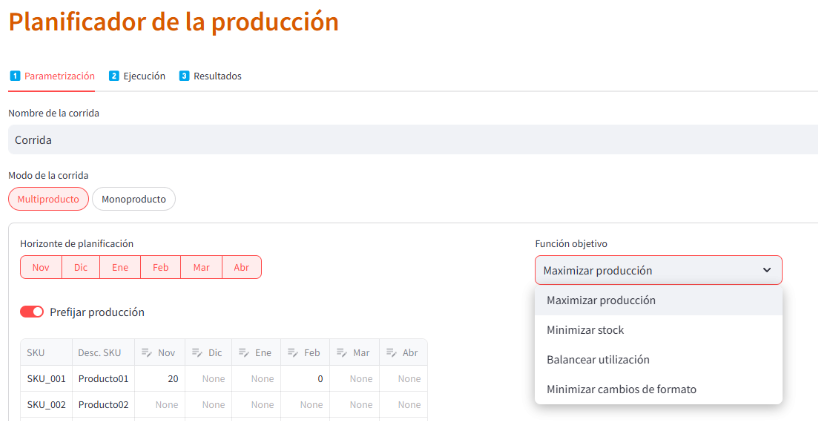

Production

planning

We develop specific tools for production planning in complex environments, where a large number of products, multiple resources (machines, operations, HR) and operational constraints are involved.

The main objective is to determine which products and volume to produce in each

period, aiming to satisfy demand while period, seeking to meet demand while minimizing production costs, maintaining coverage levels, guaranteeing raw material availability and optimizing production capacity utilization.

Multi-period

planning

- Multi-period planning for an extended horizon and with different time aggregation levels (weeks, months).

- Production resource planning for each area and team, considering available working days, work shifts and multifunctional teams.

- Sensitivity analysis on the opening of work shifts, investment of production technology in bottlenecks, among others.

Production constraints

- Compliance with forecasted demand.

- Optimal utilization of available production capacity (machine-hours and man-hours) of each piece of equipment.

- Complex production logics and multiple manufacturing recipes, considering set-up and change-over times.

- Utilization of available raw materials and generation of material requirements forecasting (MRP).

- Projection of stock levels and satisfaction of inventory rules.

Benefits and potentials

01

Generation of production plans for multiple SKUs.

02

Maximize the use of production capacity.

03

Minimize production and inventory costs.

Capturas de pantalla

Financial management of the production plan

How to make the best use of idle capacity? Which products should be kept in stock and in what quantity?

Comprehensive economic analysis

Economic analysis involving labor costs, energy, stock immobilization, restocking, among others.

Investment in production capacity

Strategic analysis on the incorporation of new capacity and equipment, as well as the allocation of additional shifts in specific areas.

Sensitivity analysis

Sensitivity analysis to evaluate the impact of variations in demand and costs on production planning.